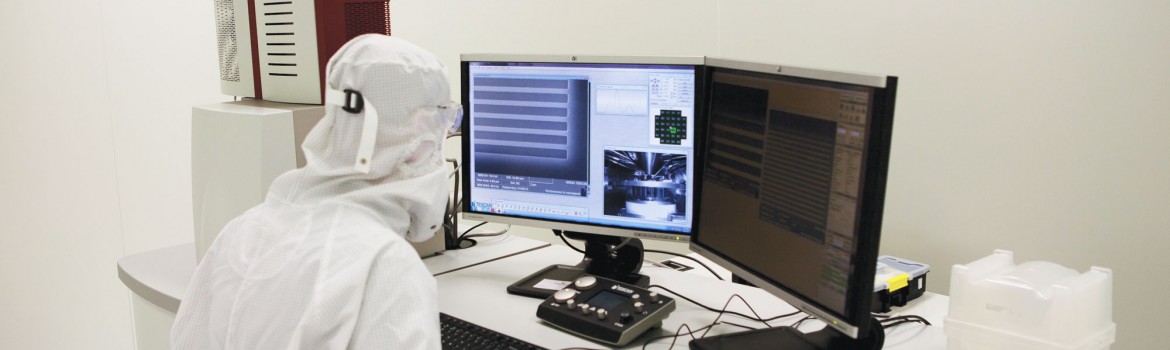

Silicon waveguide technology is processed on 6” wafer scale, thin SOI layer 220nm active device and 3μm oxide buried material configurations. Low loss high index contrast submicron size waveguide are fabricated by CMOS compatible process in order to realize dense Photonic Integrated Circuit; due to high line flexibility, fast prototyping and low/medium production can be achieved.

The technology available at INPHOTEC supports the realization of structures with minimum feature size in the range of 50 to 70nm and can guarantee the realization of components with building blocks like:

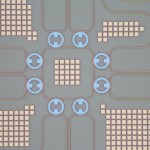

- Ring resonators

- Thermal tuning structures achieved by silicon embedded resistor or overlay metal

- P and N junctions for direct modulation

- WDM structures

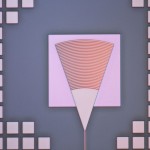

- Edge coupler with silicon taper and medium contrast layer

- Surface gratings with different designs, shapes and materials to enlarge the bandwidth and reduce the coupling losses