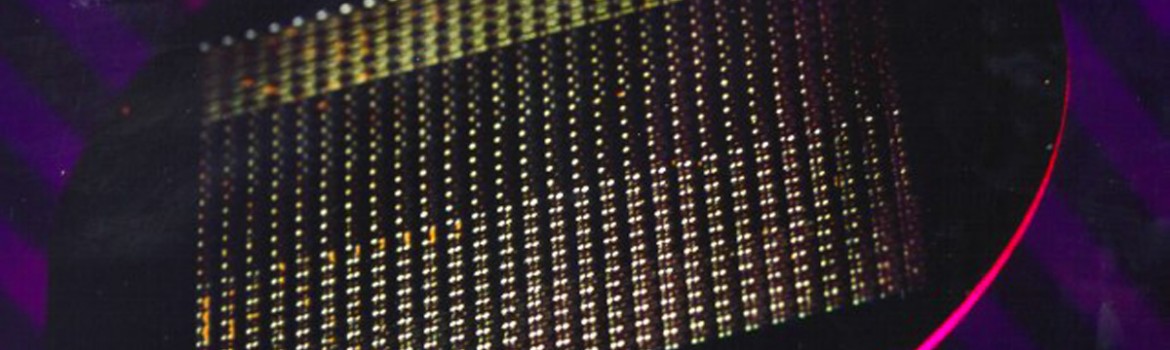

Definition of high precision patterns and structures on wafer, using lithography, is obtained with two main equipment:

ELECTRON BEAM VECTOR HB6 HR

Defines submicron and deep submicron process features definitions with the following reference parameters:

- This system is able to define submicron and deep submicron patterns and structures with the following reference parameters:

- Thermal Field Emission (TFE) electron gun

- High energy column (max 100kV)

- 25 MHz pattern generator

- 18 bits beam deflection

- Minimun beam spot size

- Maximum field size 0.524mm @100kV, 0.819mm @50kV Laser interferometer stage positioning correction

- Laser height measurement on substrate

- 32 levels dose assignment

- Temperature & mechanical vibration control

- Minimum linewidth: 30 nm ±20% (100μm field size @100keV)

- Stitching and overlay accuracy: ≤40 nm mean+3 sigma (500μm field size @100keV)

- 12-wafer air-lock capacity

- Piece-parts to 8’’ wafers, 6’’ mask capability

KARL SUSS MA6 BA6

This machine defines large patterns >0.7 µm and uses optical exposure system with tool set at 365 nm and has a guaranteed resolution of 0.7 µm. The system has the process capability to align front to back wafer surface with alignment accuracy ≤+/-1.5 µm